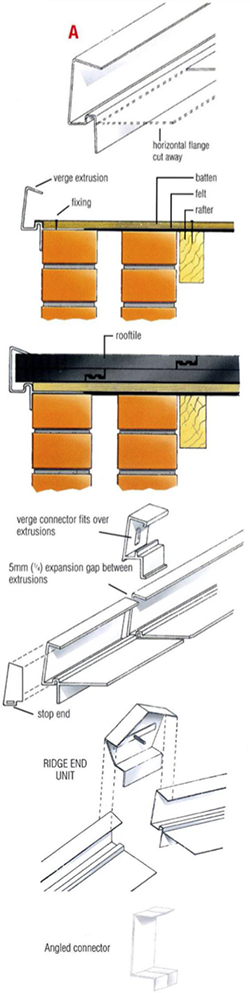

Continuous Dry Verge System Fitting Instructions

Continuous dry verge system is designed to fit on the gable end of buildings between the underside of the battens and the outer wall of the roof ladder.

- Ensure the gable wall is reasonably level and free from projections.

The roofing felt and battens should be laid across the cavity and the battens finished flush with the outer wall or the outer edge of the bargeboard. Take a length of verge extrusion and plumb cut the upper end. Cut the verge extrusion approximately 150mm longer than the rafter. Remember to allow 10mm between the left and right verge at the ridge for expansion and fitting the ridge cap. - At the eaves end of the verge, cut a line the length of one tile between the horizontal flange and the fin (see A on diagram). This allows the verge extrusion to fit or the tiling fillet or felt support tray at the eaves end. The bottom flange of the verge extrusion is then pushed between the wall/roof ladder and the batten. Fix through both the batten and verge into the wall.

OR

- Alternatively the verge cut and angled appropriately 250mm from the eaves end or near the first batten at the eaves, leave a 5mm gap for expansion. Fit the smaller offcut of the verge with the flange under the batten, ensuring that the length extends approximately 50mm past the line of the fascia into the gutter. Use the angled connector which should be glued over the angled cuts for a neat finish.

- The tiles are then laid in the usual manner ensuring that the verge tiles are inserted fully into the verge extrusion where the top flange will hold them fully.

- At the eaves end the verge should be cut square, flush to the lower tile. The lower fin of the verge may require slight trimming to avoid it interfering with the gutter.

- A small notch may be required in the wall side of the gutter to accommodate the verge channel ensuring that the water drains effectively into the gutter.