Bedding Details

Trench Preparation

Trenches should not be excavated too far in advance of pipe installation and should be supported by trench boxes where required by Health and Safety requirements.

Trenches should be as narrow as practicable, generally the pipe diameter + 300 and 600mm. Where multiple pipes are installed in a trench sufficient spacing should be allowed between them to ensure that there are no voids and the material can be fully compacted. Local soft spots in the trench base should be excavated and filled with a suitable compacted granular material.

The bedding material is laid below the Condron Twinwall Pipe to provide uniform support and to permit small adjustment of the pipe’s line and level. All bedding material is to be compliant with the engineers’ specification. No temporary supports (blocks of bricks, stones, wood, metal or other similar objects) should ever be used to prop the pipe during the installation process as it can damage the pipe integrity and cause pipe deformation.

Side-fill Placement

After a section of the pipe has been installed and successfully tested, the side-fill, the most important structural component of the fill, should be placed. The material should be placed evenly on both sides of the pipe, and compacted in accordance with the specification. Single-sized coarse granular materials, such as stone or gravel, may achieve the necessary density without compaction.

Compaction of these materials is recommended where trench walls are relatively soft and weak. For well-graded granular soils compaction will be necessary.

It is important that compacting equipment does not come into contact with the pipe at any stage of compaction. The side-fill material should normally extend a minimum 100mm above the pipe crown.

Backfill Placement

The backfill material that lies within 300mm of the pipe crown should be free from particles stones exceeding 40mm diameter.

Heavy compaction should not be applied until the cover to the pipe is a minimum of 300mm in order to avoid the imposition of large stresses to the pipe. The material that is placed more than 300mm above the pipe crown should be placed and compacted in layers not greater than 300mm thick or in compliance with the specification.

It is important that trench sheets or trench box, if used to support the trench, are removed progressively prior to compaction of the side-fill and backfill. Ref: Clause 505 of MCDRW.

Safety

Health and Welfare at Work (Construction) Regulations 2005. These notes are a brief summary of safety precautions based on the 2005 Regulations made under the Safety, Health and Welfare at Work Act 2005. It is the responsibility of employers, employees, and the self-employed, to ensure that legal requirements are complied with.

Particular attention is drawn to the Safety, Health and Welfare at Work (Construction) Regulations 2013 and other legislation setting out the duties of owners, employers and employees in relation to the construction and maintenance of buildings.

Above notes are given for general information guidance only, and are not to be taken as comprehensive. All Condron Concrete Works Drivers have Personal Protective Equipment such as Hard Hats, Steel – Toe Boots, Safety Jackets and have completed SOLAS Safe pass Training.

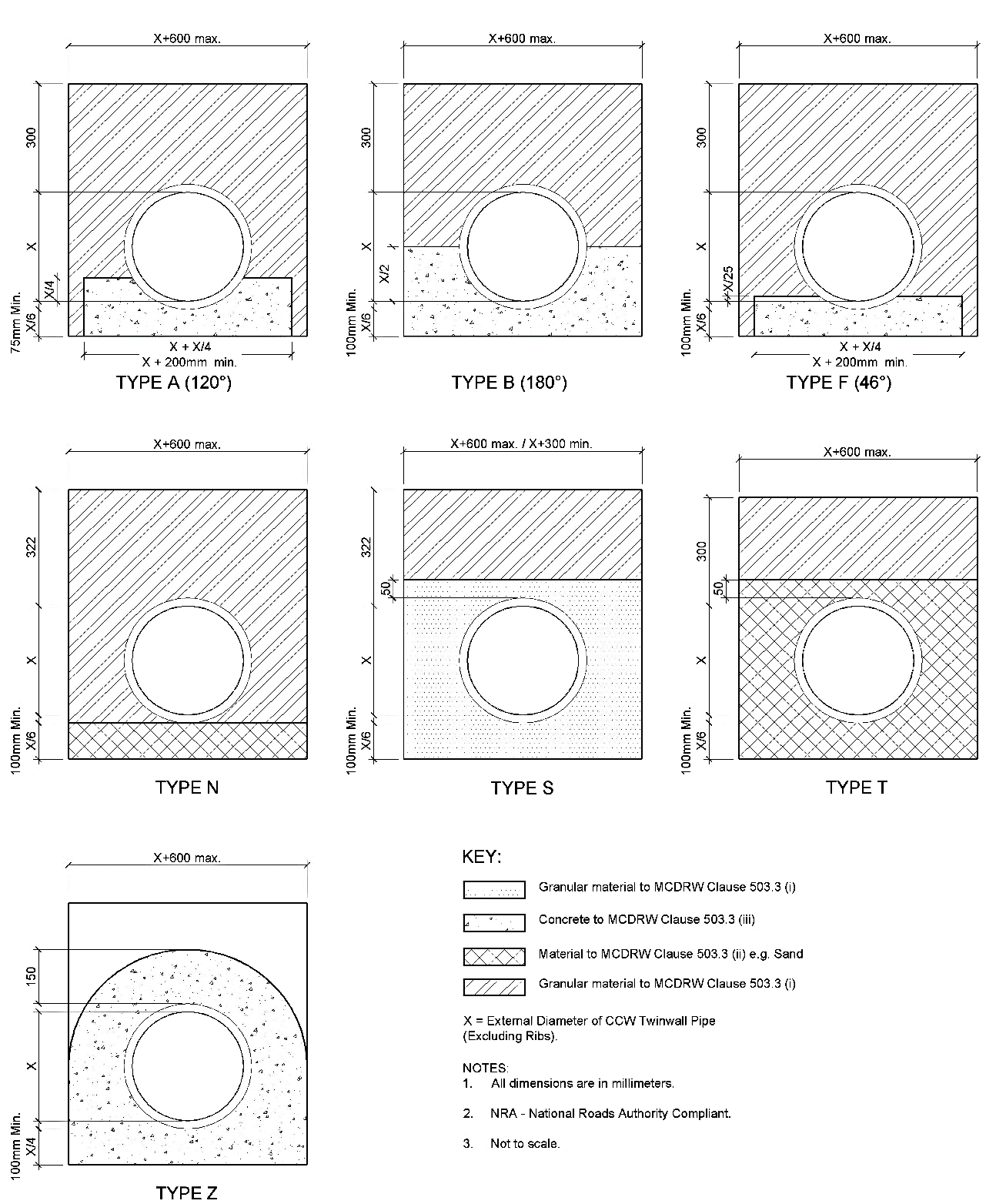

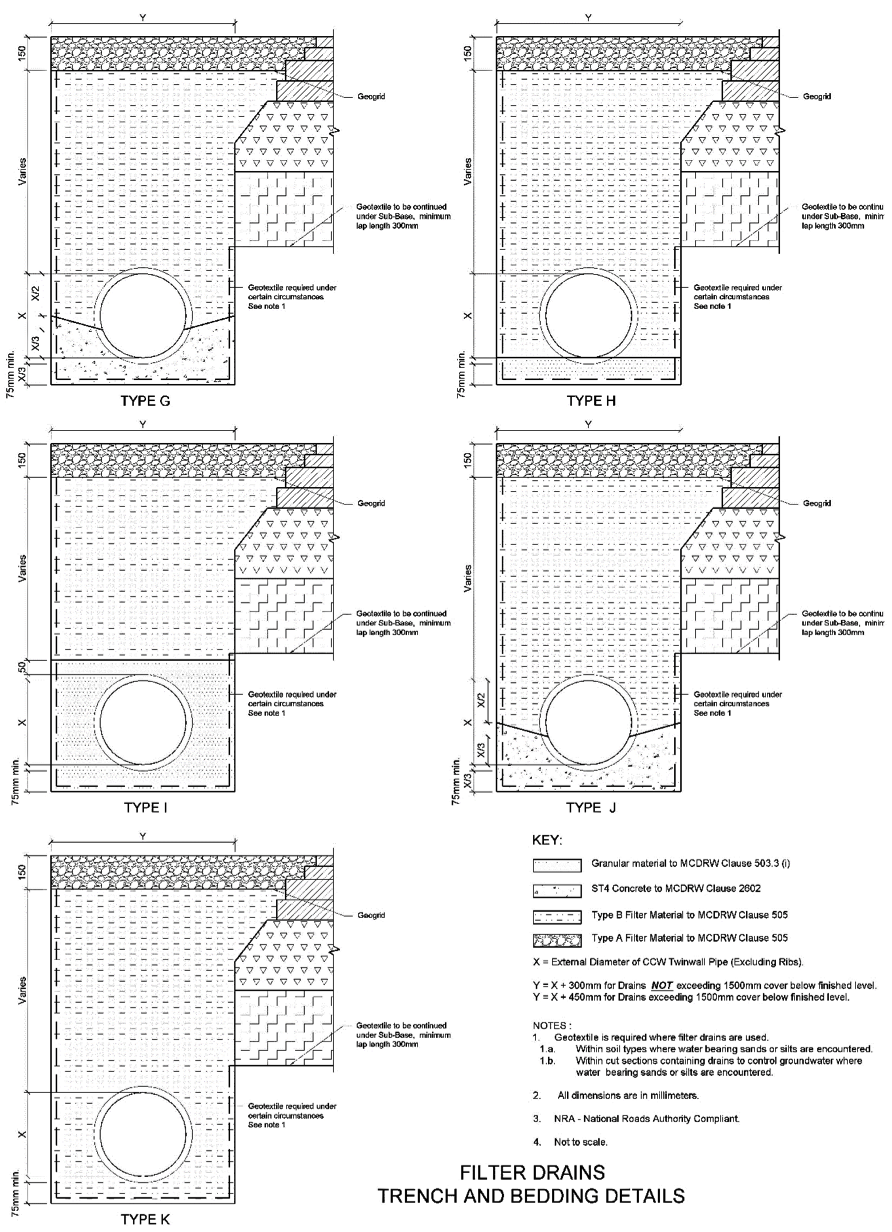

SURFACE WATER DETAILS

Surface water drain trench and bedding details

Standard bedding details Condron Concrete Works Twinwall Pipes to the NRA Manual of Contract Documents for Road Works (MCDRW).

Notes:

All Dimensions are in millimetres.

X = pipe diameter

Type S is the preferred granular bed and surround detail.

Type Z is recommended where depths of cover are less than 1.2m. Joint filler board shall be placed in contact with the end of the socket at a pipe joint and shall extend through the full thickness of the concrete in contact with the pipe. These should be placed at each pipe joint.