During production there is continuous quality control on all critical parts of the production process to ensure wall thickness, internal diameter, weight, external diameter and that socket diameters are all within dimensional tolerances.

|

|---|

| Quality Control |

| Test |

| Appearance (visual inspection) |

| Dimensional accuracy |

| Perforation dimensions and appearance |

| Impact resistance |

| Short term stiffness |

In our purpose built lab, continuous assessment is carried out for melt flow index, ring stiffness, ring flexibility, impact resistance, heat resistance, internal pressure tests and jointing tests to the latest International and European Standards. Sealing ring are certified to EN681 and designed to exceed 0.5bar while under deflection and shear.

| | | | |

|---|

| Standard Twinwall Pipes | | | | |

| ID Ø mm | OD Ø mm | Length (m) | Weight kg/m (Approx.) | Socketed / Straight |

| 100 | 116 | 6 | 0.70 | Straight |

| 150 | 175 | 6 | 1.20 | Socketed |

| 225 | 260 | 6 | 2.38 | Socketed |

| 300 | 345 | 6 | 4.10 | Socketed |

| 375 | 435 | 6 | 6.80 | Socketed |

| 450 | 500 | 6 | 8.20 | Straight |

| 600 | 680 | 6 | 18 | Socketed |

| 750 | 842 | 6 | 25 | Socketed |

| 900 | 1016 | 6 | 33.5 | Socketed |

| | | | |

| | | | |

|---|

| Perforated Twinwall Pipes | Perforated Twinwall Pipes | Perforated Twinwall Pipes | Perforated Twinwall Pipes | Perforated Twinwall Pipes |

| ID Ø mm | OD Ø mm | Length (m) | Weight kg/m (Approx.) | Socketed /Straight |

| 100 | 116 | 6 | 0.70 | Straight |

| 150 | 175 | 6 | 1.20 | Socketed |

| 225 | 260 | 6 | 2.38 | Socketed |

| 300 | 345 | 6 | 4.10 | Socketed |

| 375 | 435 | 6 | 6.80 | Socketed |

| 450 | 500 | 6 | 8.20 | Straight |

| 600 | 660 | 6 | 18 | Socketed |

| 750 | Made to Order | 6 | 25 | Socketed |

| 900 | Made to Order | | | Socketed |

| | | | |

| | | | | | | |

|---|

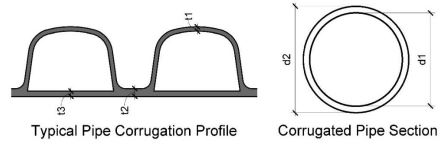

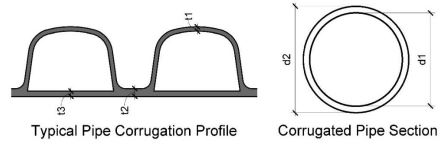

| Pipe Dimensions | | | | | | | |

| Nominal internal pipe diameter d1 (mm) | External pipe diameter d2 (mm) | t1 optimum (mm) | t2 optimum (mm) | t3 optimum (mm) | Nominal length (m) | Nominal weight (kg/m-1 Approx.) | Pitch (mm) |

| 100 | 116±2 | 0.6 | 1.2 | 0.8 | 6 | 0.70 | 13.25 |

| 150 | 175±2 | 0.68 | 1.4 | 1.3 | 6 | 1.20 | 26.61 |

| 225 | 260±2 | 1.28 | 1.55 | 1.19 | 6 | 2.38 | 34.80 |

| 300 | 345±2 | 1.26 | 2.25 | 1.53 | 6 | 4.10 | 41.13 |

| 375 | 435±2 | 1.42 | 2.7 | 2.1 | 6 | 6.80 | 50.27 |

| 450 | 500±2 | 2.1 | 3.4 | 2 | 6 | 8.20 | 56.55 |

| 600 | 680±3 | 2.8 | 4.6 | 3 | 6 | 18 | 75.40 |

| 750 | 842±4 | 3.2 | 5.2 | 3.4 | 6 | 25 | 87.97 |

| 900 | 1016±5 | 3 | 5.2 | 3.7 | 6 | 33.5 | 105.56 |

| | | | | | | |

| | | | | |

|---|

| Perforated Pipe Details | | | | | |

| Internal pipe Ø (nominal)(mm) | No. of slots per dwell | No. of dwells per metre | Slot length (mm) | Slot width (mm) | Permeable area min.(mm2/m-1) |

| 100 | 6 | 74 | 10-15 | 1.2-1.5 | 5256 |

| 150 | 6 | 39 | 15-32 | 1.0-1.5 | 3510 |

| 225 | 6 | 29 | 10-30 | 3.0-3.5 | 5220 |

| 300 | 6 | 25 | 15-31 | 3.0-3.5 | 6750 |

| 375 | 6 | 20 | 20-42 | 2.7-3.5 | 6480 |

| 450 | 4 | 18 | 35-50 | 3.0-3.5 | 7560 |

| 600 | 4 | 14 | 120 | 4.5-5.5 | 30240 |

| 750 | Made to order | | | | |

| 900 | Made to order | | | | |

| Semi-Perforated Pipe Details | | | | | |

| Internal pipe Ø (nominal)(mm) | No. of slots per dwell | No. of dwells per metre | Slot length (mm) | Slot width (mm) | Permeable area min.(mm2/m-1) |

| 100 | 3 | 74 | 10-15 | 1.2-1.5 | 2628 |

| 150 | 3 | 39 | 15-32 | 1.0-1.5 | 1755 |

| 225 | 3 | 29 | 10-30 | 3.0-3.5 | 2610 |

| 300 | 3 | 25 | 15-31 | 3.0-3.5 | 3375 |

| 375 | 3 | 20 | 20-42 | 2.7-3.5 | 3240 |

| 450 | 2 | 18 | 35-50 | 3.0-3.5 | 3780 |

| 600 | 4 | 14 | 120 | 4.5-5.5 | 15120 |

| 750 | Made to order | | | | |

| 900 | Made to order | | | | |

Land Drainage Pipe (Coils)

Manufactured from recycled plastic, Land Drainage Pipes are manufactured in a range of internal diameters 64mm, 80mm, 94mm, 100mm and 150mm. Available in varying coil lengths and is specifically designed to for land drainage management. It offers significant improvements in areas where poor drainage negatively affects ground stability

The flexible nature of the Land Drainage Pipe makes it suitable for agricultural applications, road drainage, sports and leisure projects and drainage of water logged areas.

| | | | |

|---|

| Land Drainage Pipe - Manufactured in accordance to B.S.4962 | | | | |

| ID Ø mm | OD Ø mm | Length (m) | Weight kg/m (Approx.) | Socketed /Straight |

| 64 | 80 | 50 or 100 | 0.30 | Straight |

| 94 | 110 | 50 or 100 | 0.36 | Straight |

| 100 | 116 | 50 or 100 | 0.37 | Straight |

| 150 | 175 | 35 | 0.80 | Straight |

Specific lengths available on request, please contact our sales team for further information.

Advantages:

Advantages:

The Condron Concrete Land Drainage pipes is to B.S.4962 is an effective sub-surface drainage system and can assist in the following;

- Reduces ponding in low permeable soils.

- Lowers surrounding water table to assist flood relief.

- Drier soils greatly increase agricultural and recreational activities.

- Suitable for all types of soils.

- Slot perforated for superior drainage.

- A full range of fittings available for various connections.

| |

|---|

| Material properties/ Typical values | 2EA3F2 |

| Property | Test method reference |

| Bulk Density | EN ISO 60: 2000 |

| Melt Mass Flow Rate (MFR) | EN ISO 1133: 2005 Procedure A (2.16 Kg) |

| Ash Content | EN ISO 3451 Method A |

| Izod Impact | EN ISO 180 Type A |

| Tensile Stress @ Yield | EN 527-2 Type A1 |

| Tensile Strain @ break | EN 527-2 Type A1 |

| Oxidation Induction time | BS EN 728 |

| | | | | | | | | | |

|---|

| Coupler Fitting | Pipe Diameter Offset | Pipe Diameter Offset | | | | | | | |  |

| 100mm | 150mm | 225mm | 300mm | 375mm | 450mm | 600mm | 750mm | 900mm | |

| Straight | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | Made to order | Made to order | Made to order | |

| | | | |

|---|

| Table 3 Coupler Dimensions | | | | |

| Nominal internal/external pipe diameter (mm) | Internal Diameter | Internal Diameter (mm) | Nominal length (mm) | Nominal seal height (mm) |

| pipe diameter (mm) | At first dwell (mm) | At second dwell (mm) | Nominal length (mm) | Nominal seal height (mm) |

| 100/129 | 118.0 | 118.0 | 145.0 | 10.4 |

| 150/260 | 178.5 | 178.5 | 180.0 | 17.2 |

| 225/260 | 264.5 | 264.5 | 220.0 | 27 |

| 300/345 | 346.5 | 346.5 | 245.0 | 31 |

| 375/435 | 439.5 | 439.5 | 330.0 | 38.7 |

| 450/435 | 508.0 | 508.0 | 335.0 | 36.9 |

| | | | | | | |

|---|

| T - Junctions Fitting | | Pipe Diameter Offset | | | | |  |

| 100mm | 150mm | 225mm | 300mm | 375mm | 450mm | |

| 100mm | ✓ | | | | | | |

| 150mm | ✓ | ✓ | | | | | |

| 225mm | ✓* | ✓ | ✓ | | | | |

| 300mm | ✓* | ✓ | ✓* | ✓* | | | |

| 375mm | ✓* | ✓* | ✓* | ✓* | ✓* | | |

| 450mm | ✓* | ✓* | ✓* | ✓* | ✓* | ✓* | |

| 600mm | Made to order | | | | | | |

| 750mm | Made to order | | | | | | |

| 900mm | Made to order | | | | | | |

Note: * denotes fabricated and pressure tested to order

| | | | | | | |

|---|

| Y - Junctions Fitting | | Pipe Diameter Offset | | | | |  |

| 100mm | 150mm | 225mm | 300mm | 375mm | 450mm | |

| 100mm | ✓ | | | | | | |

| 150mm | ✓ | ✓ | | | | | |

| 225mm | ✓* | ✓ | ✓ | | | | |

| 300mm | ✓* | ✓ | ✓* | ✓* | | | |

| 375mm | ✓* | ✓* | ✓* | ✓* | ✓* | | |

| 450mm | ✓* | ✓* | ✓* | ✓* | ✓* | ✓* | |

| 600/680 | Made to order | | | | | | |

| 750/842 | Made to order | | | | | | |

| 900/1016 | Made to order | | | | | | |

| | | | | | | |

|---|

| Bends | Pipe Offset | | | | | |  |

| 11.25º | 15º | 22.5º | 30º | 45º | 90º | |

| 100mm | ✓ | ✓ | ✓* | ✓ | ✓ | ✓ | |

| 150mm | ✓* | ✓ | ✓* | ✓ | ✓ | ✓ | |

| 225mm | ✓* | ✓* | ✓* | ✓* | ✓ | ✓ | |

| 300mm | ✓* | ✓* | ✓* | ✓* | ✓ | ✓ | |

| 375mm | ✓* | ✓* | ✓* | ✓* | ✓* | ✓* | |

| 450mm | ✓* | ✓* | ✓* | ✓* | ✓* | ✓* | |

| 600mm | Made to order | | | | | | |

| 750mm | Made to order | | | | | | |

| 900mm | Made to order | | | | | | |

| | | | | | | |

|---|

| Reducer Fitting | Pipe Diameter | Pipe Diameter | | | | |  |

| 100mm | 150mm | 225mm | 300mm | 375mm | 450mm | |

| 100mm | | ✓ | ✓ | ✓ | ✓ | ✓ | |

| 150mm | ✓ | | ✓ | ✓ | ✓ | ✓ | |

| 225mm | ✓ | ✓ | | ✓ | | | |

| 300mm | ✓ | ✓ | ✓ | | | | |

| 375mm | ✓ | ✓ | ✓ | ✓ | | | |

| 450mm | ✓ | ✓ | ✓ | ✓ | | | |

| 600mm | | | | | | | |

| 750mm | | | | | | | |

| 900mm | | | | | | | |

Note: * denotes fabricated and pressure tested to order

PA Saddle Description

A Plastic Adaptor saddle to connect a 160mm OD PVC lateral pipe into a large diameter Twin Wall or Ribbed Sewer pipe DN 300mm – DN 600mm.

| | |

|---|

| Pipe Diameter | Saddle Diameter Offset |  |

| 150mm | |

| 300mm | ✓ | |

| 375mm | ✓ | |

| 450mm | ✓ | |

| 600mm | ✓ | |

Standard Couplings Description

Designed for sewerage, drainage and all non and low pressure applications up to 2.5 bar.

When used individually or combined with bushes, Flexseal Standard Couplings have many applications in the construction, repair and maintenance of pipe systems:

- As a joint for plain ended pipes

- Repair and maintenance of existing pipelines

- Connecting short and cut lengths of pipe

- Making post construction connections to an existing pipeline

- Reconnection of laterals on renovated sewers

| | | | | | | |

|---|

| Pipe Diameter | | Repair Couplings | | | | |  |

| Pipe Diameter | 100mm | 150mm | 225mm | 300mm | 375mm | 450mm | |

| 100mm | ✓ | | | | | | |

| 150mm | | ✓ | | | | | |

| 225mm | | | ✓ | | | | |

| 300mm | | | | ✓ | | | |

| 375mm | | | | | ✓ | | |

| 450mm | | | | | | ✓ | |

Pipe Lubricant NEUTREX® for plastic pipes: a white, water miscible paste based on synthetic materials. Standard application: general plumbing and construction. Neutrex is approved for drinking water applications after DVGW as well as WRAS.

Condron Concrete Works Twinwall Pipes can be delivered with any order for Roof Tiles, O.G. Pipes, S&S Pipes, Manhole Rings, Manhole Covers and Road Gullies on the same delivery.

| |

|---|

| Internal Pipe Ø | Approx. Number of Structural Twinwall pipes per bale |

| 100mm | 77 |

| 150mm | 36 |

| 225mm | 14 |

| 300mm | 8 |

| 375mm | 5 |

| 450mm | 4 |

| 600mm | 2 |

| 750mm | 1 |

| 900mm | 1 |