Concrete Pipes

OGEE pipes which are used mainly for Surface Water Drainage, Land Drainage etc. Diameters range from 150mm to 1200mm with perforated pipes available up to 600mm.

Specials of all products can be manufactured and supplied “to order”.

Ogee pipes are manufactured a metre long. S&S vary from 1.25 metres for 150mm and 225mm diameter, to 2 metres for 300mm diameter, and 2.5 metres for all other sizes.

All our pipes are manufactured and certified to relevant European (EN) and Irish (IS) Standards Specifications and are regularly inspected by officials from National Standards Authority of Ireland (NSAI). Daily routine Quality Control is also carried out by our own team of engineers to ensure that highest standards are maintained at all times.

Materials

All our products are manufactured using highest quality aggregates, which come from our own quarries and sand pits. Our batching and mixing procedures are fully computerised producing low water to cement ratio, high strength, concrete.

Reinforcement

Reinforcement cages required for the Spigot & Socket pipes are produced from Cold Drawn High Tensile Steel on our automatic welding machines.

I.S.6: Concrete Sewer Pipe

This specification deals with the manufacture and properties of flexible jointed concrete pipes and fittings, either reinforced with steel or unreinforced, intended to be used for the conveyance of sewage, or sewage and surface water at atmospheric pressure. These test requirements may be found in I.S. 6: 2004 and are to be used in conjunction with ISEN 1916: 2004. These new Standards are also be available from NSAI.

Material Comparison

To assist in choosing between rigid and flexible pipes, consider the following:

| Attribute | Concrete | Plastic |

| Proven Durability | YES | NO |

| Non-Flammable | YES | NO |

| High Impact Strength | YES | NO |

| Structural Strength Principally in pipe rather than surround | YES | NO |

| Rigid Under Load | YES | NO |

| Copes with poor quality installation | YES | NO |

| Copes with high pressure water jetting | YES | NO |

| Contains Rats in sewers | YES | NO |

| Self weight inhibits floatation | YES | NO |

| Diameters from DN 225 To DN 2100 | YES | NO |

| Availability of complete pipeline system | YES | NO |

Heights of chamber sections are as shown on the table.

| Permissible angles under I.S.6: as follows | Table 6 |

| Nominal Size mm | Permissible Angle |

| 150 | 90°, 45°, 22½° |

| 225 | 90°, 45° |

| 300, 375, 450, 525, 600 | 45° |

The requirements of I.S.6 2004 and ISEN 1916 are such that the pipes are tested at the place of manufacture to ensure that they are adequate for the purpose intended.

The following tests are carried out in compliance with the Standard on a daily basis by our Quality Control Team and are audited regularly by N.S.A.I. to ensure full compliance with the current Standard.

| Test | Purpose |

| Crush Test (proof) | To ensure reinforced pipes stand up to 80% of the minimum Crush Load before developing cracks. |

| Crush Test (min.) | To ensure all pipes are capable of withstanding the specified minimum Crush Load without collapse |

| Hydrostatic Test | To assess the permeability of the pipe walls |

| Water Absorption | To assess the quality and density of the concrete |

| Joint Deflection | To ensure the flexibility of the pipe joints to the minimum angular deflection specified. |

| Joint Straight Draw | This enables us to guarantee joints will remain watertight with a 20mm gap between pipes. |

| Joint Shear | To prove that a joint will remain watertight when a load is applied. |

| Cover to Reinforcement | To monitor that all the reinforcement is protected by minimum of 15mm cover |

Gauging of 1050mm Ø Pipe

In-house Material Testing

Production Quality Control

Quality Control Inspection

750mm ø I.S. 6 Pipe undergoing Hydrostatic Test

1200mm ø I.S. 6 Pipe undergoing Crush Test

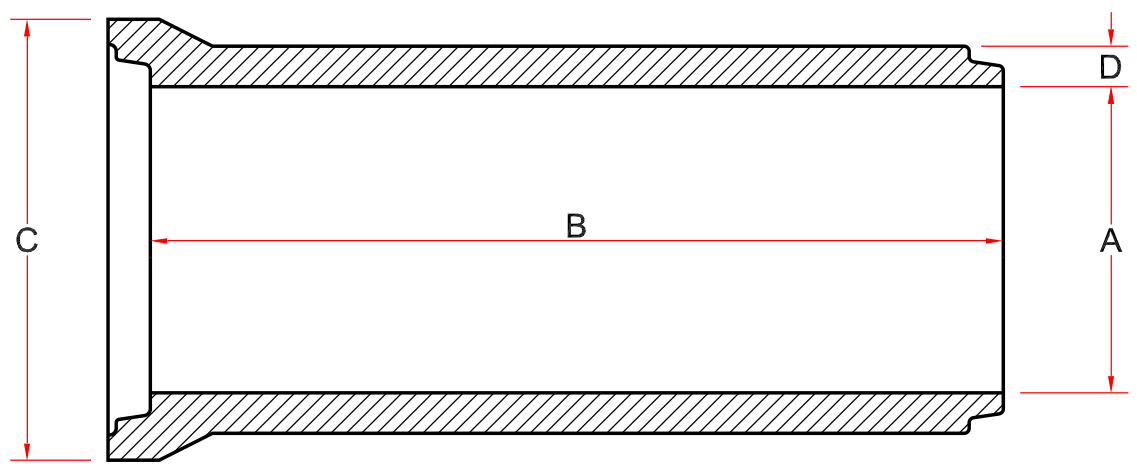

Spigot and Socket Type Pipe (S & S)

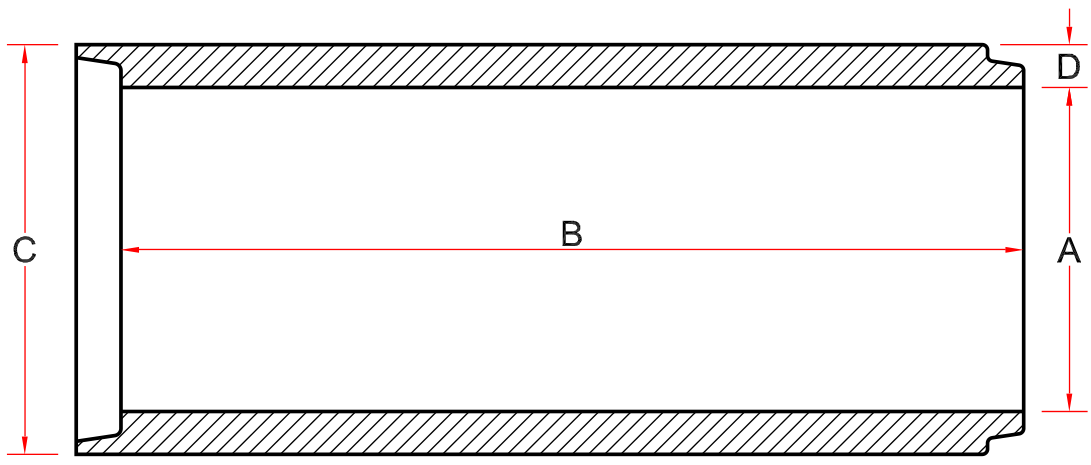

Rebated Type Pipe

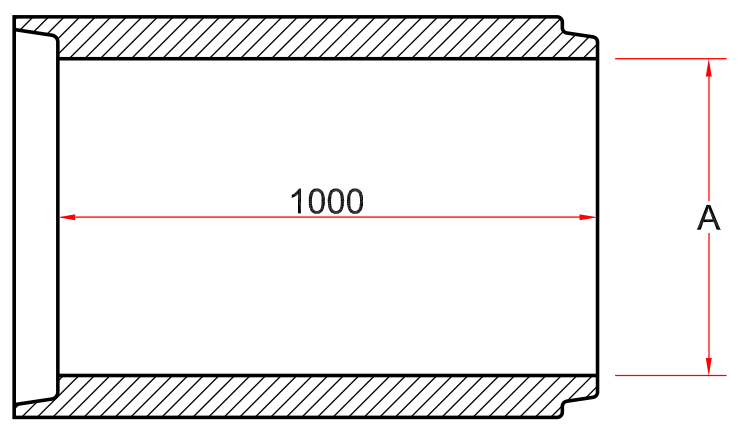

Ogee Pipes

| “A” Internal Diameter | B Length | Approx. Wall Thickness (mm) | Approx. Weight in kgs |

| 225mm | 1 Metre | 35 | 65 |

| 300mm | 1 Metre | 37 | 86 |

| 375mm | 1 Metre | 38 | 124 |

| 450mm | 1 Metre | 46 | 167 |

| 525mm | 1 Metre | 47 | 210 |

| 600mm | 1 Metre | 54 | 278 |

| 750mm | 1 Metre | 75 | 470 |

| 900mm | 1 Metre | 95 | 710 |

| 1050mm | 1 Metre | 100 | 870 |

| 1200mm | 1 Metre | 110 | 1110 |

Ogee pipes are manufactured to I.S. 166: 1972 specification

Rebated Type Pipe

| A | B | C | D | ||

| Pipe | Length (m) | Approx. Outside (mm) O/D | Approx. Wall Thickness (mm) | Approx. Weight in kgs | Pipe Type |

| 150mm | 1.25 | 290 | 33 | 80 | S & S |

| 225mm | 1.25 | 392 | 38 | 122 | S & S |

| 300mm | 2.0 | 505 | 60 | 358 | S & S |

| 375mm | 2.5 | 606 | 65 | 565 | S & S |

| 450mm | 2.5 | 707 | 69 | 730 | S & S |

| 525mm | 2.5 | 808 | 77 | 980 | S & S |

| 600mm | 2.5 | 909 | 91 | 1240 | S & S |

| 675mm | 2.5 | 1008 | 97 | 1520 | S & S |

| 750mm | 2.5 | 1016 | 111 | 1840 | S & S |

| 900mm | 2.5 | 1183 | 122 | 2380 | S & S |

| 1050mm | 2.5 | 1420 | 128 | 3040 | S & S |

| 1200mm | 2.5 | 1605 | 138 | 3880 | S & S |

| 1350mm | 2.5 | 1805 | 152 | 4640 | S & S |

| 1500mm | 2.5 | 2012 | 150 | 5800 | S & S |

| 1650mm | 2.5 | 2155 | 178 | 6900 | S & S |

| 1800mm | 2.5 | 2310 | 203 | 8240 | S & S |

| 2100mm | 2.5 | 2525 | 211 | 9560 | Rebated |

| 2400mm | 2.5 | 2866 | 230 | 11600 | Rebated |

Rocker Pipes

| Diameter | Length |

| 225mm to 600mm | 0.6m |

| 750mm | 1.0m |

| 900mm | 1.25m |

| 1050mm to 2400mm | 1.0m |