Manholes

Manholes

Condron Concrete Works produce a complete range of manhole components, all of which are certified to I.S. 420: 2004 in conjunction with ISEN 1917

Advantages of Precast Manholes:

The main advantages of precast concrete manhole units over in situ concrete construction are:

- Units are factory produced to I.S. 420: 2004 and I.S. EN 1917

- They are manufactured in wide range of sizes and depths.

- They are simple to assemble requiring relatively unskilled labour on site.

- Units are capable of being constructed as flexible watertight structures.

- They are supplied fitted with steps to EN 13101: 2002 Type D Class 1

- The structure is durable with its own inherent strength.

- Elastomeric joint seals in compliance to EN681. Butyl sealant strips also available as a seal option.

- Proprietary watertight system available in 1200⌀ using ‘wide wall’ (130mm wall) and 1350mm, 1500mm units. Lifting anchor eyes available on request.

- Avoid concrete surround of manhole structure where wall thickness >125mm (I.W Spec) With use of our 1200, 1350, 1500mm Proprietary watertight system

- All bases and Perfect bases have min wall thickness of 130mm meeting Irish water specification for Proprietary watertight system

- Base Units:

- Chamber/Inspection Units:

- Cover Slabs:

- Quality Control and Testing

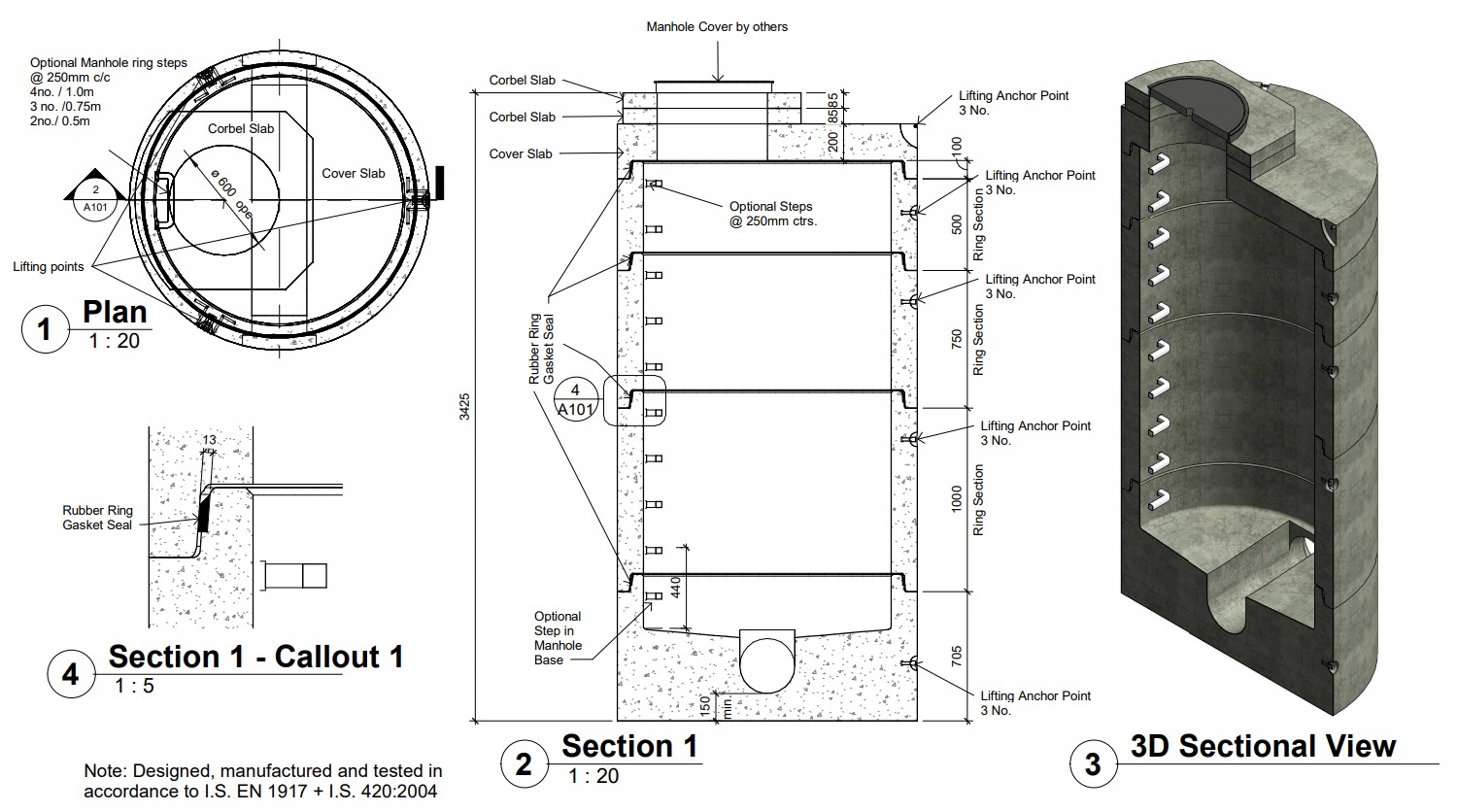

- Typical Manhole Construction

The diameter of our Manhole Base is 1200mm and as can be seen from Table 11, an extensive range of channel sizes and floor plans are available which would cater for the vast majority of site requirements. The all socketed units are designed so that a seal can be provided on all connections, with double spigoted sections available for concrete pipes connecting the outlet to the socket of the first downstream pipe. The 150mm, 225mm and 300mm channel sizes are also available with gaskets suitable for use with a wide range of plastic pipes. Heights and Weights of Manhole Bases are as shown on the tables below.

Heights and weights of Wet Cast Manhole Bases 1200 Ø ID

Table 10

| Channel Size | Overall height (Approx.) | Effective Height (Invert to top of Base Shoulder) | Approx Weight in kgs for Base Types | |

| Type 2 (cross) | Type 4 (universal) | |||

| 150mm | 600mm | 384mm | - | 1250 |

| 225mm | 675mm | 459mm | - | 1450 |

| 300mm | 750mm | 534mm | 1700 | - |

AVAILABLE MANHOLE BASE PLANS IN 1200MM Ø BASES

Table 11

| Plan Type | 1 | 2 | 3 |

| 150mm Diameter Channel |  | ||

| 225mm Diameter Channel |  | ||

| 300mm Diameter Channel |  | ||

150mm Universal Wet Cast Base and EN681 Gasket position

All chamber sections are fitted during manufacture with 350mm wide plastic coated aluminium rung steps, which are spaced 250mm apart, thereby providing a uniform step interval in all units.

The black polyethylene covering on the steps is resistant to nearly all media and also prevents sparking when walked on with iron-mounted boots. The steps comply to EN 13101: 2002 Type D Class C

Chamber Rings can be supplied reinforced if required. All sections are jointed using our CS 202 Butyl Sealant (or Elastomeril Jointseals to EN681) giving an immediate and flexible watertight joint.

Heights of chamber sections are as shown on the table.

NOTE: All chamber sections are to be stored vertically on site to prevent rolling.

Heights and weights of Chamber Rings

Table 9

1200mm Wide Wall 1350mm and 1500mm Propriety Watertight chamber rings have 3no. cast in anchors. 2.5T Lifting clutches /eyes available on request (certified) and are compatible with anchors cast into off the shelf wetcast and perfect bases.

| Internal Diameter of Chamber Rings | Wall Thickness (Approx.) | Height (Approx Weight in kgs) | ||||

| 1.50m | 1.00m | 0.75m | 0.50m | 0.25m | ||

| 900mm | 95mm | - | 630 | - | 325 | 205 |

| 1050mm | 100mm | - | 820 | - | 420 | 215 |

| 1200mm | 110mm | - | 1120 | 800 | 570 | 290 |

| 1200mm wide wall (WTS) | 130mm | 2000 | 1350 | - | 690 | 350 |

| 1350mm | 140mm | - | 1660 | 1250 | 850 | - |

| 1350mm (WTS) | 140mm | - | 1660 | 1250 | 850 | - |

| 1500mm | 155mm | - | 2080 | 1565 | 1050 | - |

| 1500mm (WTS) | 155mm | - | 2080 | 1565 | 1050 | - |

| 1800mm | 160mm | - | 2420 | - | 1120 | - |

| 2100mm | 155mm | - | 3000 | - | 1520 | - |

| 2400mm | 230mm | - | 4700 | - | 2380 | - |

| 3000mm (WTS) | 180mm | - | 4500 | 3400 | 2250 | - |

- 2 number 32mm diameter lifting pin for 900,1050,1200mm Manhole Chamber units

- 3 number 40mm diameter lifting pins for 1350,1500,1800mm Manhole Chamber units.

- 3 number 50mm diameter lifting pins for 2100,2400mm Manhole Chamber units Lifting pins available on request (certified) – See Pg. 27,45,46 of pipe/manhole brochure HERE.

- WTS– Water Tight System units are in accordance with Irish Water Specification STD/WW/10A Note 2 & Note 15 and incorporate 3no. 2.5T Lifting anchors. 3no. 2.5T Lifting Clutches required. Certified Lifting Clutches are available on request.

- Ensure correct crainage and chains/slings used in accordance with latest health and safety regulations

The cover slabs, which are all reinforced, have a different thickness for different diameters. All are provided with a 600mm (min) diameter opes and a socketed base which allows a butyl sealant joint to the top chamber section. Optional opes available on request.

| Cover Slab Dia. | Overall Approx. Thickness | Effective Approx. Thickness | Approx. Weight (kg) |

| 900mm | 230mm | 170mm | 340 |

| 1050mm | 230mm | 160mm | 480 |

| 1200mm (Regular) | 230mm | 150mm | 580 |

| 1200mm (W.T.S)* | 240mm | 170mm | 650 |

| 1350mm | 300mm | 200mm | 1020 |

| 1500mm | 300mm | 200mm | 1260 |

| 1800mm | 300mm | 200mm | 1780 |

| 2100mm | 350mm | 230mm | 3200 |

| 2400mm | 380mm | 250mm | 4140 |

| 3000mm | 300mm | 210mm | 5500 |

*Irish Water Spec

I.S. 420: 1989, I.S. 420: 2004 and ISEN 1917 incorporates routine water absorption tests, works proof load tests, maximum load tests, cube crushing tests, cover to reinforcement, complete manhole hydrostatic test and installed step tests. Our Quality Control Team carries these tests out daily to ensure compliance to the relevant standards.

NOTE: Standard manhole covers must have level and fully compacted granular material surrounding the units during construction stage. They are designed for D400 loading uniformly distributed through the steel manhole lid. Impact loading by construction traffic may cause structural defects.